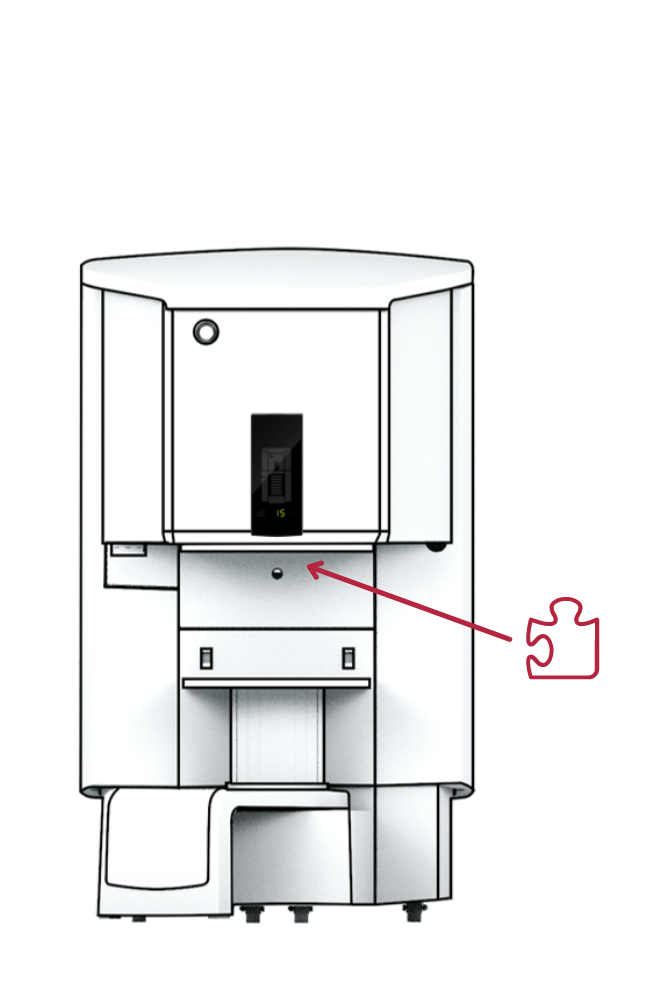

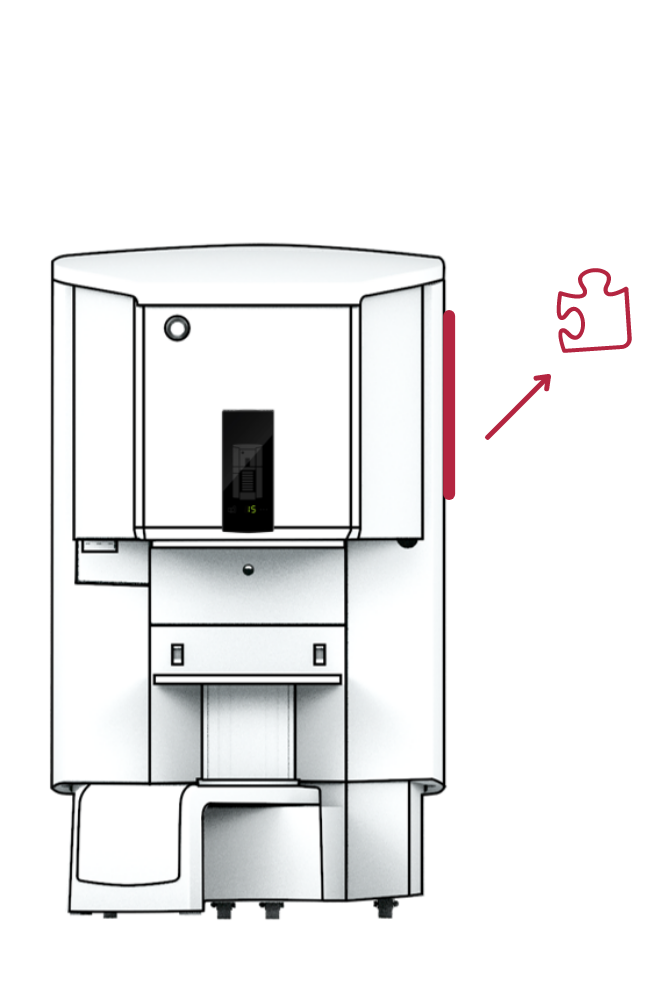

HA480 Automatic paint dispenser - Dispensers

- High-quality design

- Harbil® ZeroPurge™ Piston pump

- Fast and reliable

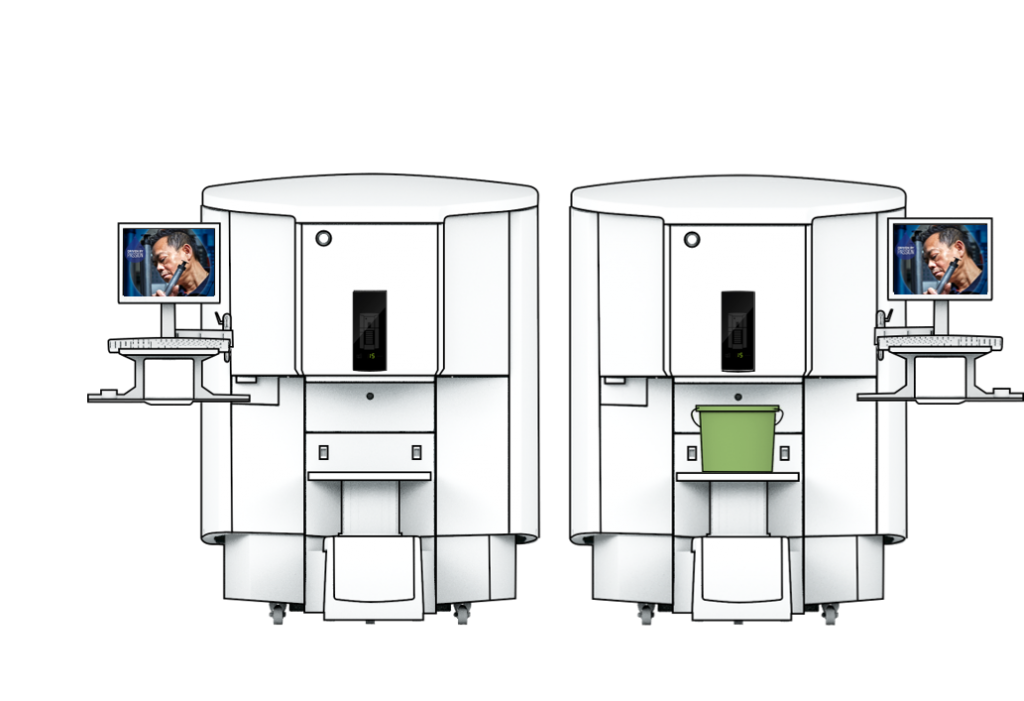

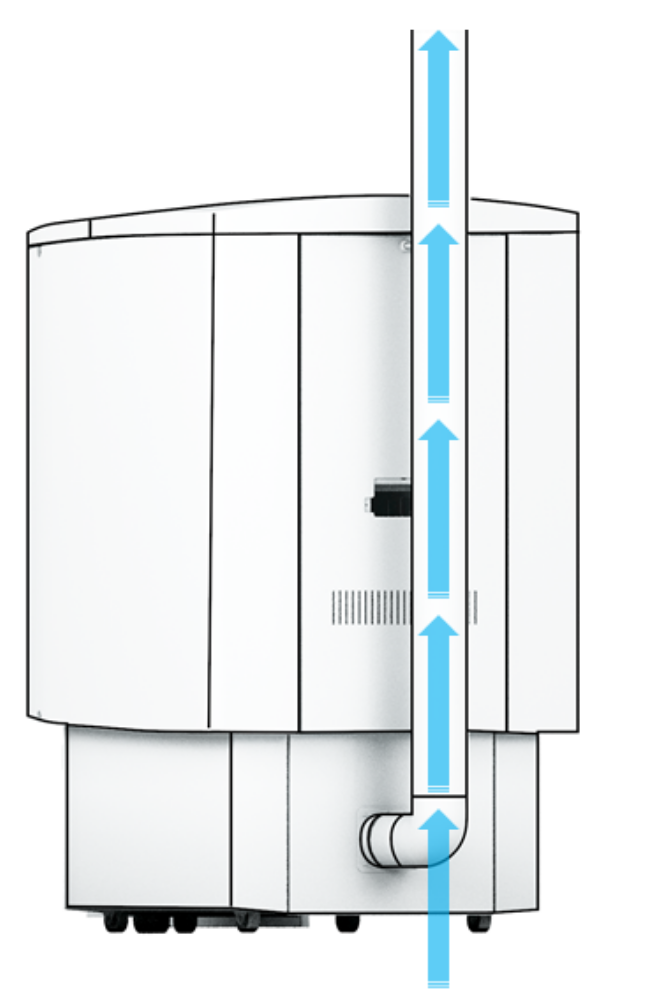

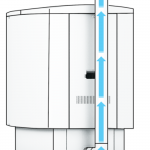

The HA480 automatic dispenser is the new standard in tinting. It is the ideal solution for DIY, medium-sized retail or service centers. The improved dispense speed, ZeroPurge™ piston pump and AutoDrive™ technology ensure future-proof efficiency and reliability for your business operation.

Specifications

- 16-32 POM/SST canisters in 2/3/6/10 l size

- ZeroPurge piston pump technology

- Universal, solvent, water based and biocide-free colorants

- Pump size: 100 ml

- Flow rate 0.8 – 1.0 l/min

- 0,05 ml smallest dispense

- Electric can table

- Electric punch (optional)

- Heating set (optional)

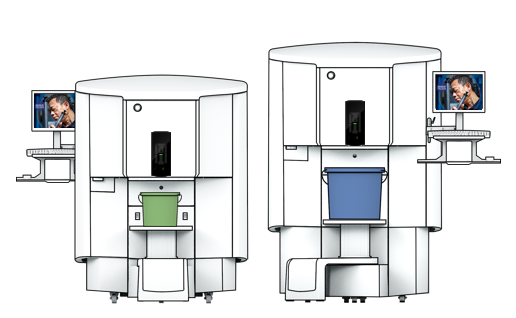

- Low/high model

- HWD 151x88x96 cm (low model)

- HWD 171x88x96 cm (high model)

For all product Insights and updates please visit:

harbilnextgen.com

Request information about the HA480 Automatic paint dispenser

A Harbil Series dispenser

The Harbil Series dispensers take tinting to the next level. Featuring innovative technology based on customer collaboration and years of development, you can be sure of superior dispensing results, even with the most challenging colorants.

Read more on harbilnextgen.com

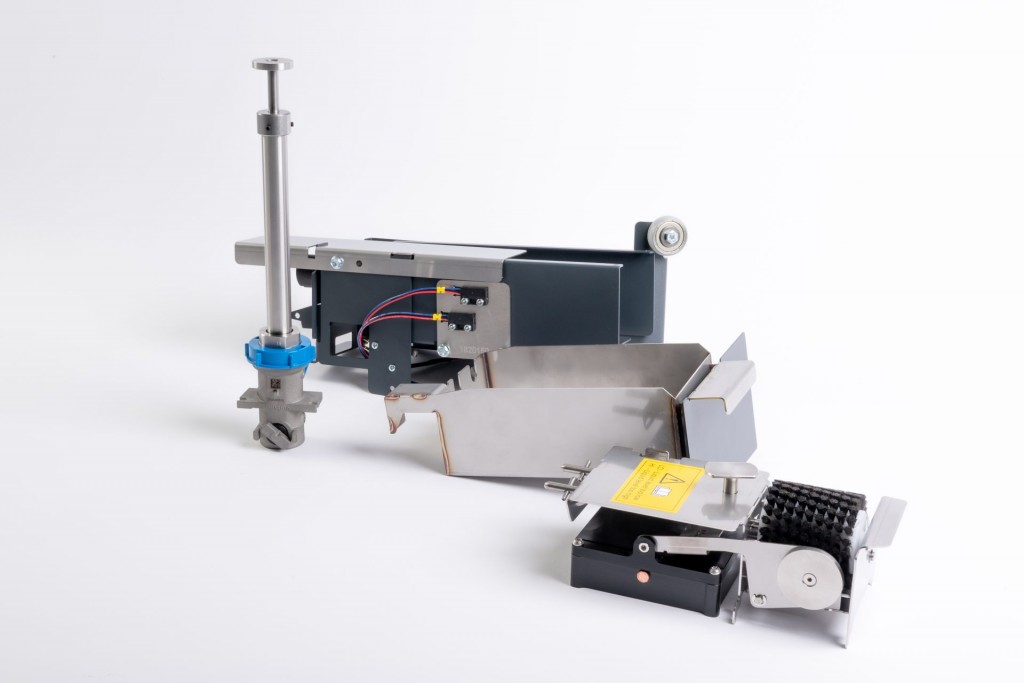

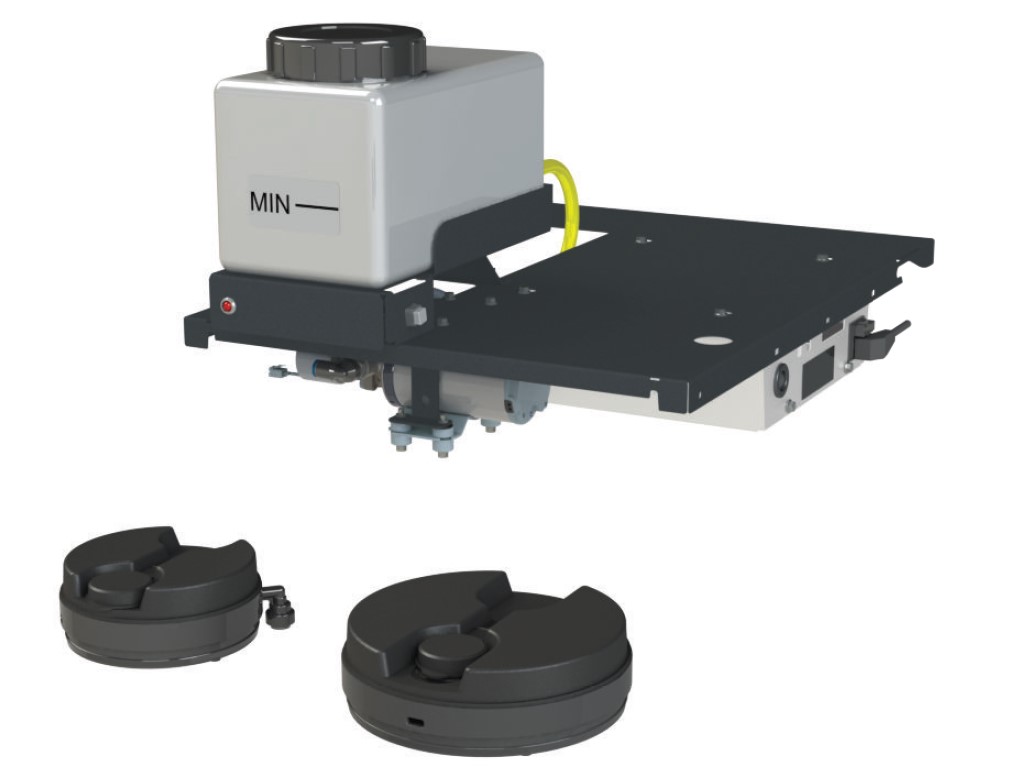

The Harbil® ZeroPurge™ Piston Pump

Optimize your operation with the ZeroPurge piston pump. This pump eliminates the manual purging process and autonomously flushes the dispense channels at night, leaving no room for idle colorant anywhere in the system.

Zero colorant waste, minimal maintenance, and a dispenser that’s always ready.

Watch the video to see more.

Technical data

General

- Automatic sequential

Solvent based, water based, universal and biocide-free colorants

Canisters

- Up to 16 - 32 canisters

- Material: polymeric/stainless steel (optional)

- Sizes: 2/3/6/10 l

Pump

- Harbil® ZeroPurge™ Piston pump

- Pump size: 100 ml

- Flow rate: 0.8 - 1.0 l/min

- Min. dispense: 0.05 ml

- Nozzle diameter: 2/4/6 mm

- Stainless steel ball valve

- Seals material: Teflon / Viton extreme / Viton

- ZeroPurge™

- Copied calibration - no recalibration required

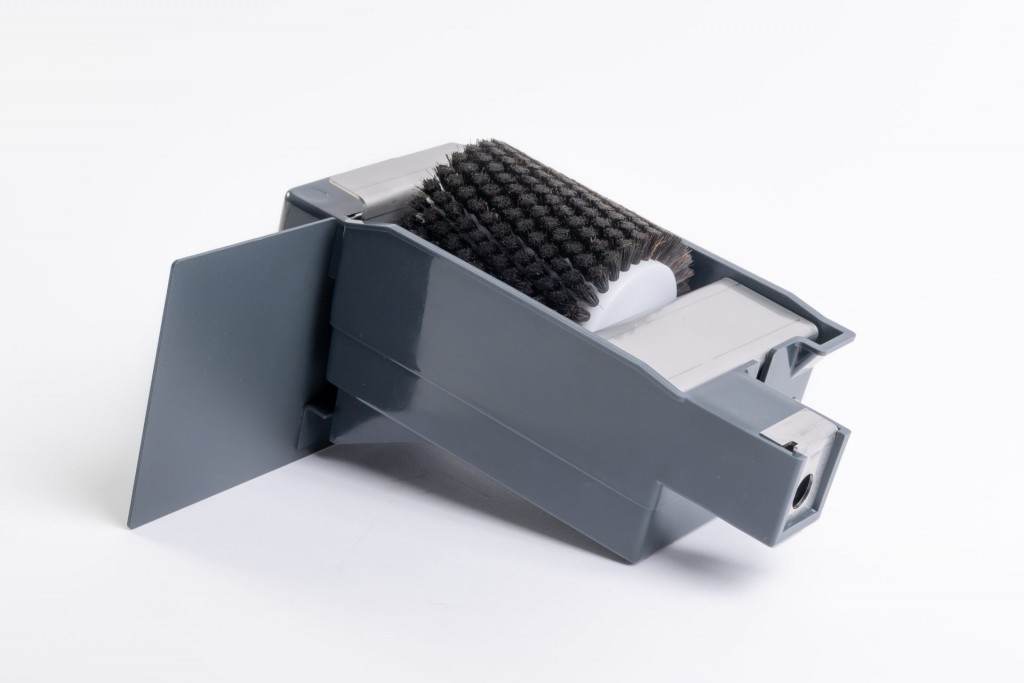

Nozzles

- Air tight - integrated nozzle closures

- Cleaning system: automatic brush & internal flush

Can table

- Electric Lift

- Dimensions: 44 x 31 cm

- Loading height: 39 cm (low model) / 55 cm (high model)

- Max. can height: 42 cm (low model) / 46 cm (high model)

- Optical can sensor / Short Range sensor (optional)

Dimension & weight

- HWD 151 x 88 x 96 cm (Low model)

HWD 171 x 88 x 96 cm (High model) - Filling height:

140 cm (Low model)

112 cm from step (Low model)

160 cm (High model)

132 cm from step (High model) - Packaging dimensions: 193 x 98 x 117 cm

- Weight - Net/Gross 193-265 / 224-296 kg

Power supply & safety

- 110V +/- 10%, 50Hz/60Hz

230V +/- 10%, 50Hz/60Hz - CE certified, UL approved

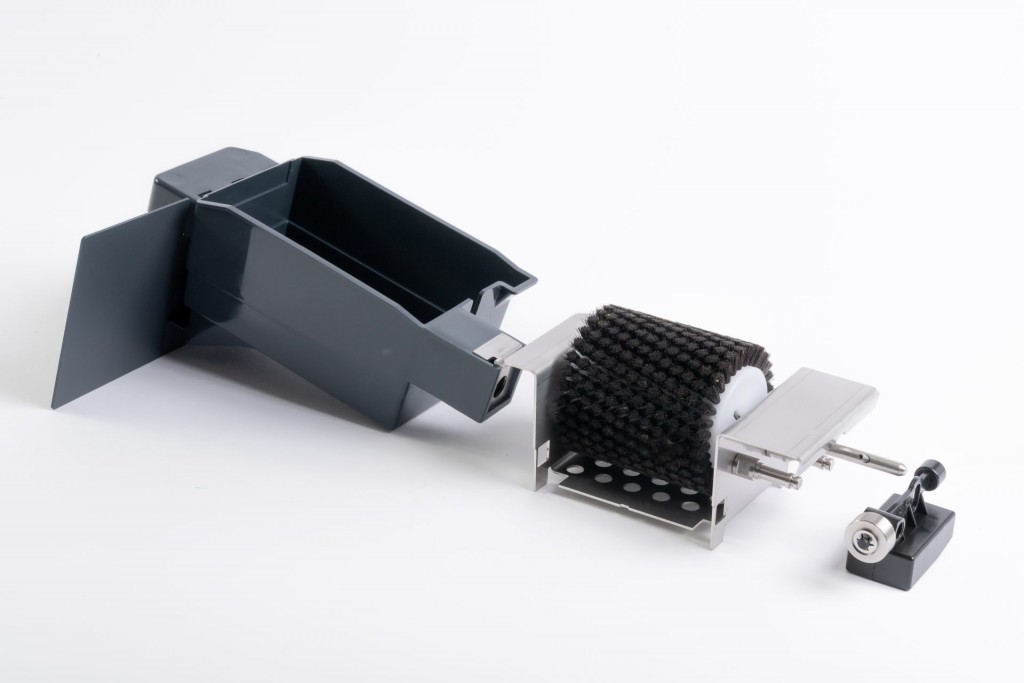

Brush

- Material: polymeric / Stainless steel (optional)

Optional

- different colours (RAL).

Options and Accessories

Options

Brush monitor

Brush monitor

A system that monitors the brush liquid level and gives the operator a warning (brush icon starts blinking) when the container is almost empty.

This item is not available for a HA180, optional for HA480 and standard for a HA680.

Brush monitor

Can positioning light HA

Can positioning light HA

The can positioning light shows the operator were the middle of the can shelf is, in order to place a can straight underneath the dispensing point of the machine.

If you are purchasing a new Harbil Series dispenser, you can order the CPL as an optional accessory. You can retrofit your current generation Harbil design by ordering a retrofit kit.

Read more in our blog: https://emea.fast-fluid.com/news/can-positioning-light/

Can positioning light HA

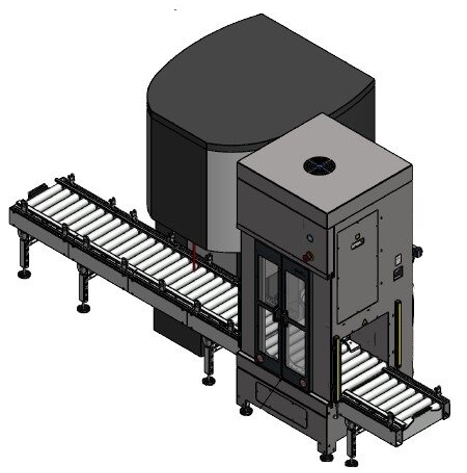

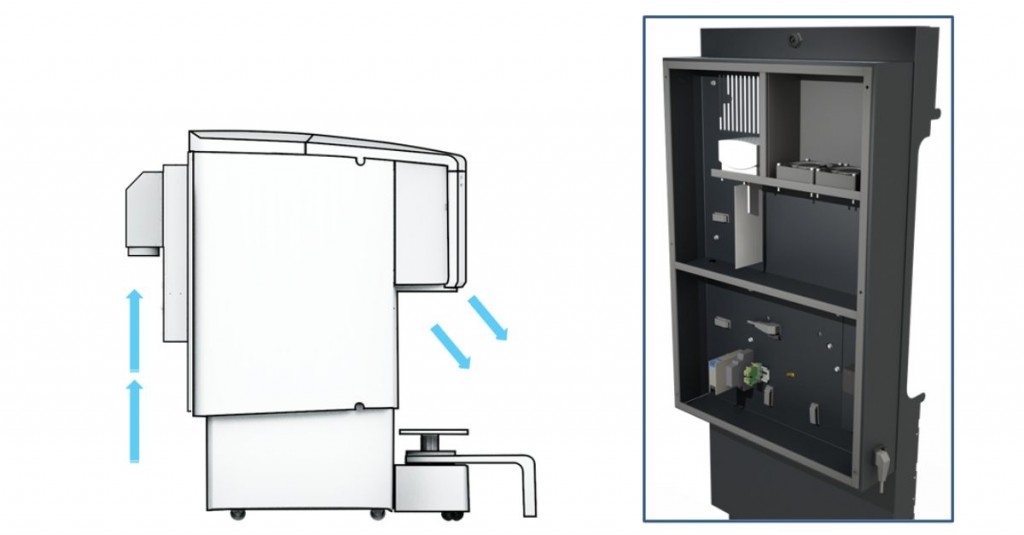

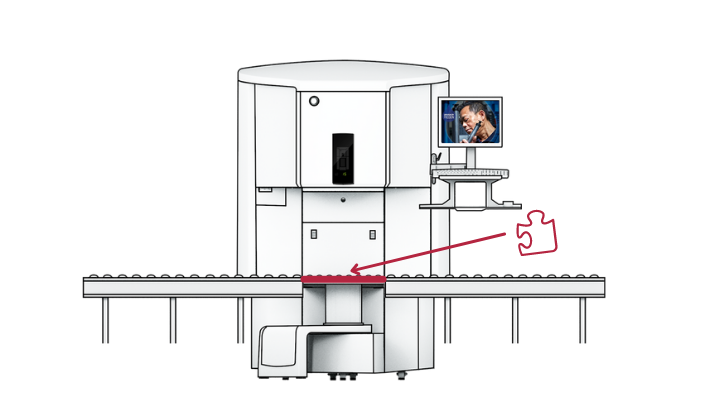

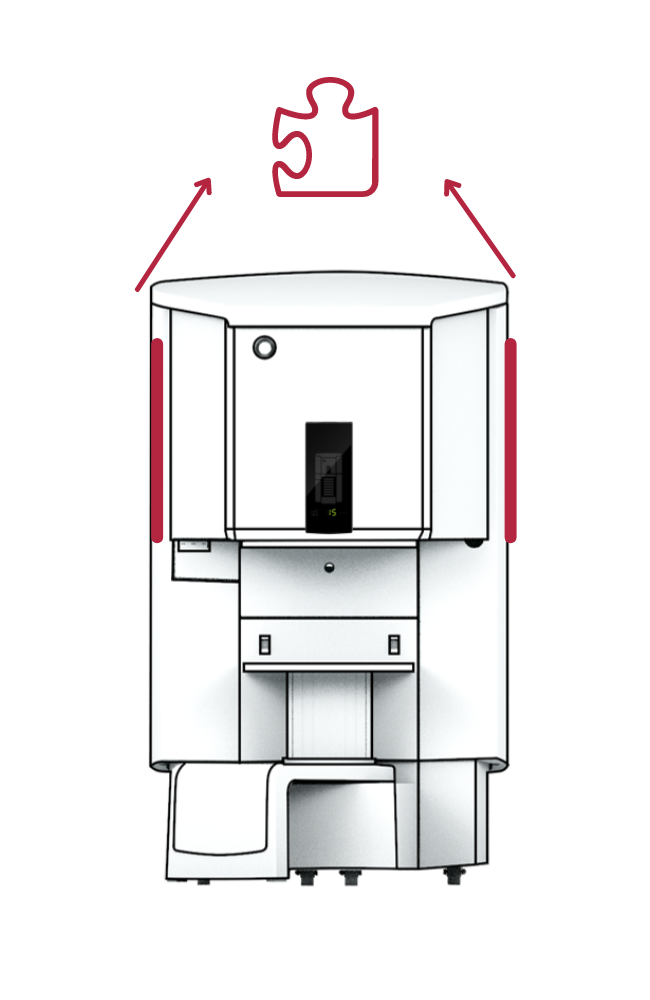

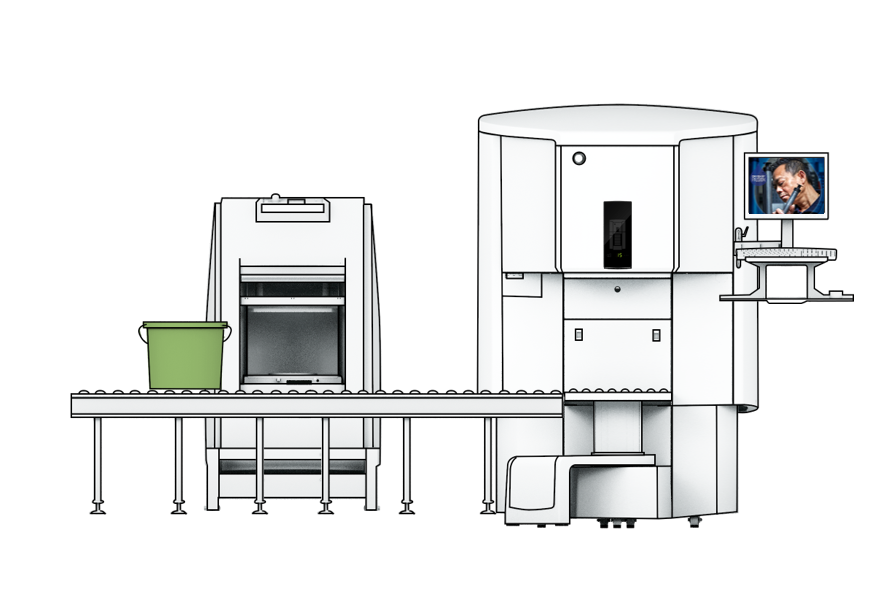

Harbil Automation

Harbil Automation

Our Harbil Automation is a new option on our HA180, HA480 and HA680, allowing our dispensers to be integrated into an automatic tinting line.

This option is ideal for large batches that are too large for a standalone dispenser or too small for an in-plant tinting system.

- High output - up to 50 buckets per hour

- Get the most out of your HA480 or HA680

- Save on labor

- Affordable solution

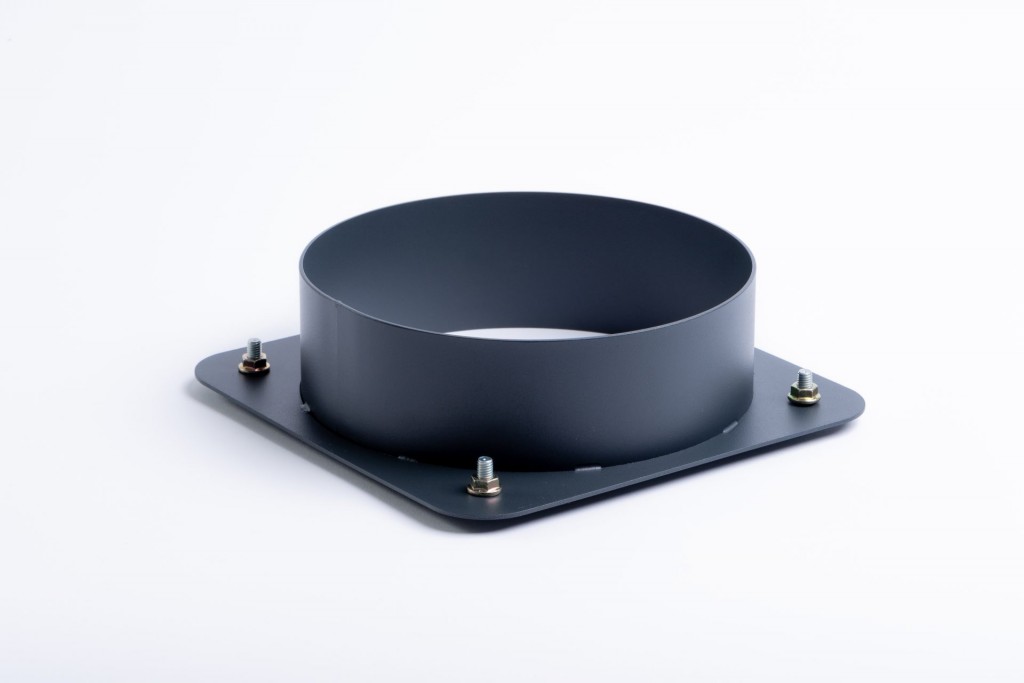

Heating set

Heating set

Integrated heating device that can be placed on the inside of a dispenser, to heaten up the temperature in order to keep your colorants in good condition.

Heating set

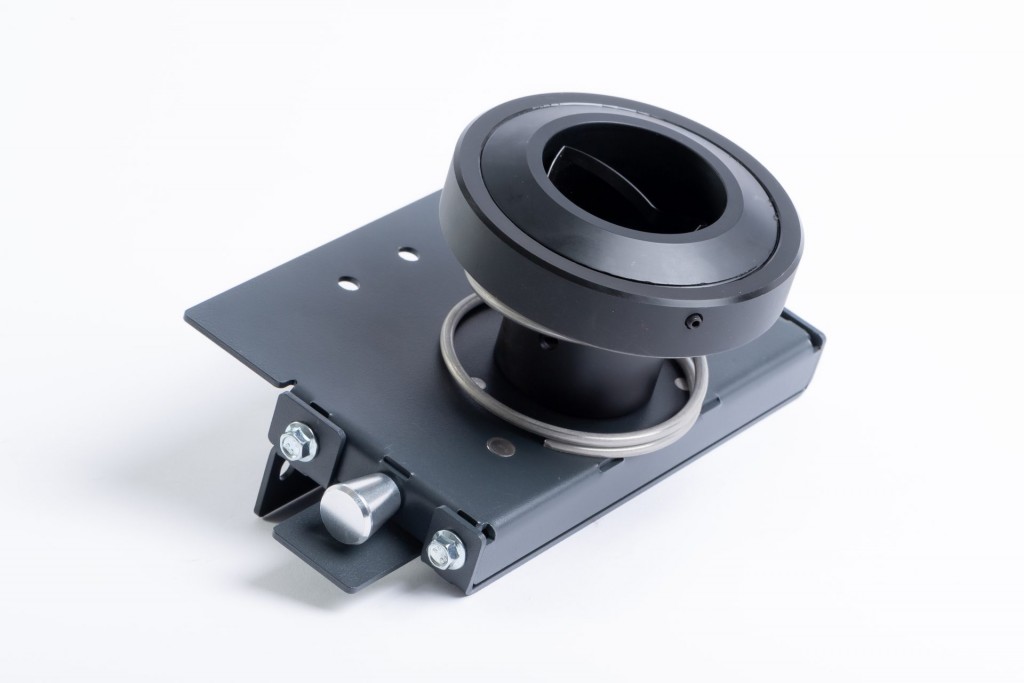

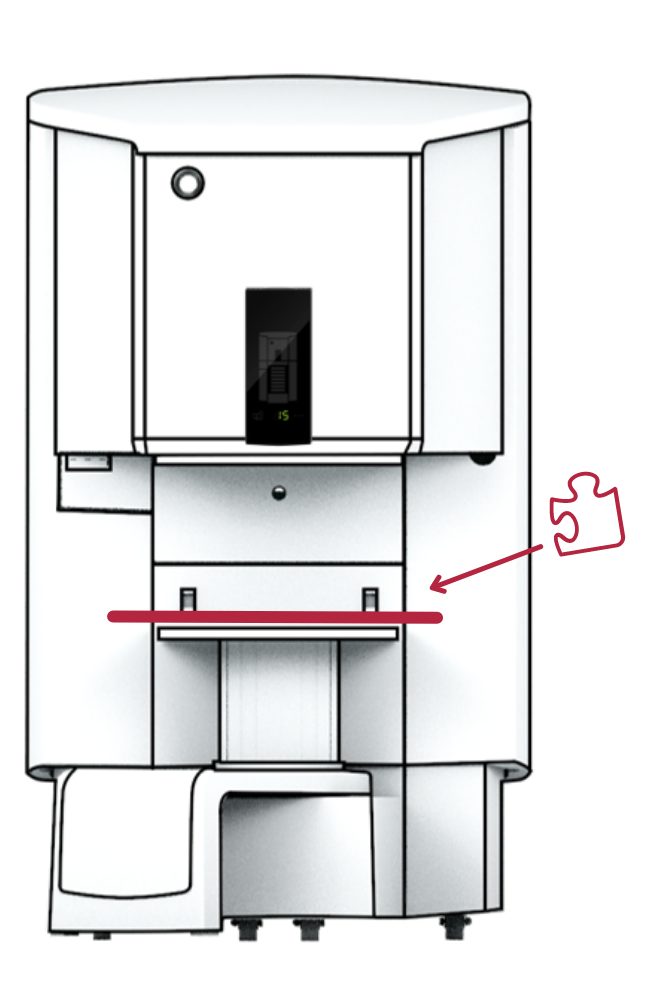

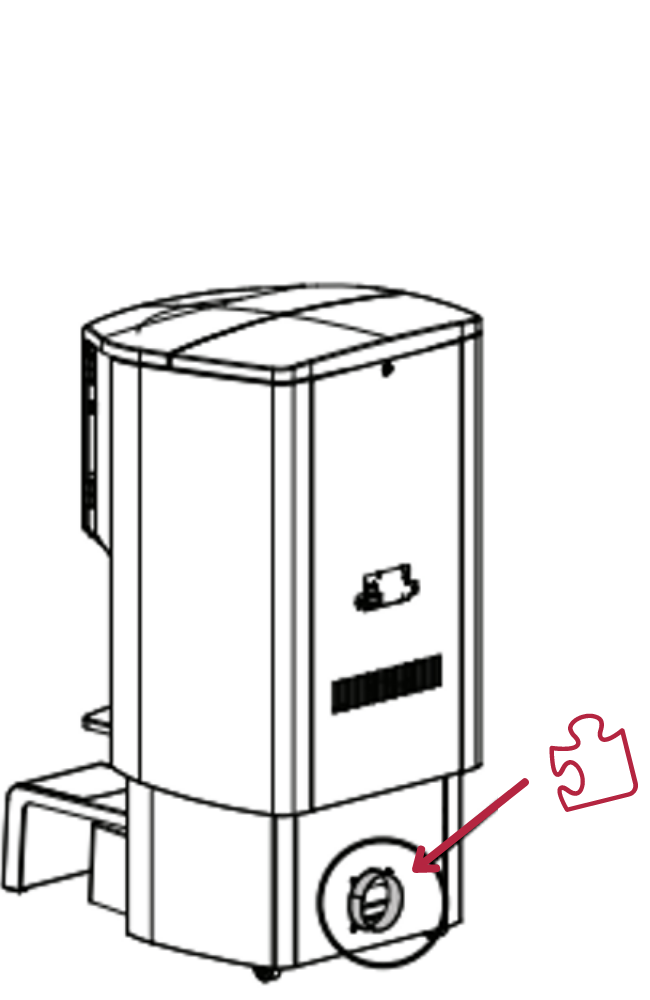

Punch 46 mm

Punch 46 mm

The integrated punching system, in order to punch a hole of 46 mm into the lid of the can after which a dispense can start.

Punch 46 mm

Sample dispensing

Sample dispensing

This option contains a sophisticated wet & dry brush system to keep the nozzle in optimal condition, key for dispensing very small amounts.

For reasonable speed (up to 0,5L/m) and accuracy, we offer the 55 ml ZeroPurge piston pump with a minimum dispense of 0.025 ml*.

* Depending on your colorant system used.

Read our blogs about sample dispensing for more details: https://emea.fast-fluid.com/news/speed-accuracy-and-precision-are-essential-in-sample-tinting/

or The difference between POS and LAB sample tinting - Fast & Fluid EMEA (fast-fluid.com)

Sample dispensing

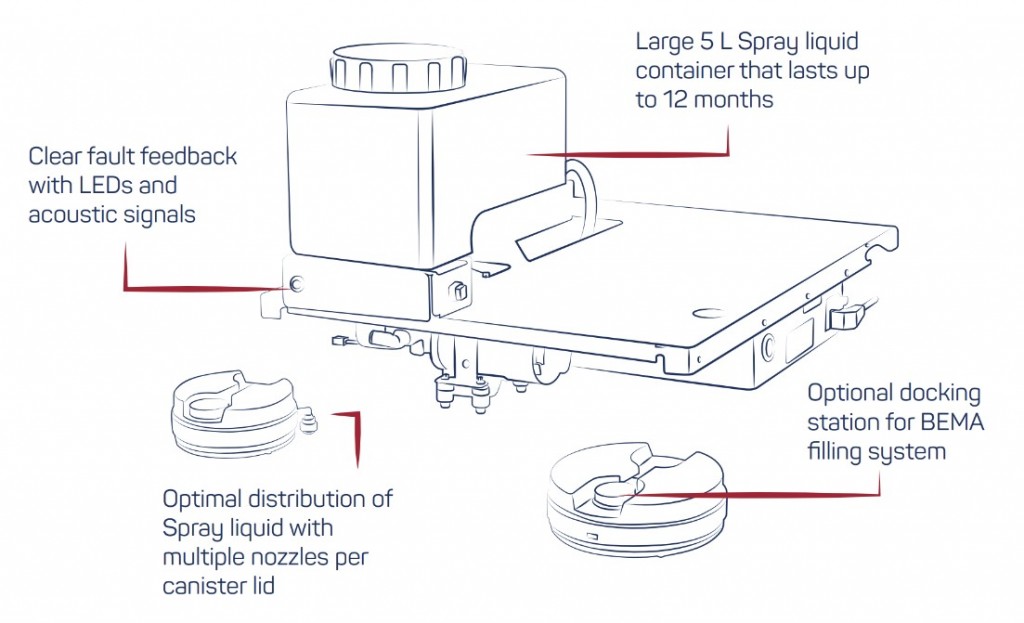

Spray

Spray

Our Spray solution, optional in HA180 and HA480, has been specifically designed to protect vulnerable biocide-free colorant systems of up to 24 colorants. Applied using our unique spraying canister lids, the Spray liquid disinfects the headspace of the canisters, providing thorough protection. Additionally, our programmable Spray system allows you to tailor the interval and duration of the Spray. This optimizes the conditioning of your colorants, ensuring they remain vibrant and healthy for longer.

Spray

UVC Solutions

UVC Solutions

Protect your colorants against mold and bacteria with our cutting-edge UVC Solutions, compatible on our HA180, HA480 and HA680.

- Consistent Protection

- Automatic head space conditioning for up to 24 canisters

- User-friendly

- Fully programmable system for effortless control.

- Advanced mold protection

- Unique UVC light-emitting lids inhibit mold and bacterial growth

- Enhanced Colorant Longevity

- Optimal UNVC distribution ensuring the colorants remain vibrant and uncontaminated

Technical Insights

Technical Insights (December 2021)

To answer the supply chain challenges caused by COVID-19 constraints and component shortages, our engineers and developers have been looking for – and finding – alternative ways to improve our tinting machines. Read about our...

Technical Insights (May/June 2021)

In this issue of Technical Insights, we have the latest updates for you on our Harbil Series, X-PROTINT dispensers and the GA480 mixer. In addition we want to share some recommendations for a safe working...

Complementary

SK550 1.1 heavy-duty paint shaker

- Medium and high volume paint turnover

- High/Low clamping detection

- Max. product weight: 40kg

- Speed: up to 680 shakes per minute - variable speed (slow start); contact us for optimal settings

PrismaPro2 POS tinting software

Control all aspects of your POS tinting software with PrismaPro. It's compatible with all our automatic dispensers. Fueled by 15 years of customer insights Prisma Pro has grown to be an outstanding solution for demanding operators and engineers.

GA480 automatic mixer

- Medium and high volume paint turnover

- Automatic, dedicated control

- Max. product weight: 40kg

- Variable speed (slow start), between 230 and 100 rpm, dynamic balance