X-PROTINT® automatic paint dispenser - Dispensers

- Increase in speed

- Reliable steel structure

- Clever operator and serviceability solutions

The X-PROTINT ® has been developed with the Asian market in mind; ready to accompany you to the level of growth you aspire. Expect dramatic increase in speed, Fast & Fluid reliability, clever operator and serviceability solutions with future-proof technology; ready for the future with VOC-free colorants.

As one of two machines from our X-SERIES, the X-PROTINT is powered by simplicity through its modular design; it has just four motors and one board, and the click-on-click-off canisters enable easy self-maintenance.

Specifications

- 16 canisters (12*2.3 l + 4*4.6 l)

- Piston pump technology

- Flow rate 0.5 l/min

- Bi-directional turntable

- Airtight nozzle closure & tubeless design

- No calibration needed

- Elegant & robust

- Front refilling

- Easy can shelf

- Universal and water based colorants

- Solvent optional

- HWD 123x82x87cm

Request information about the X-PROTINT® automatic paint dispenser

Future-proof technology

With colorant legislation rapidly changing, the X-PROTINT ® has been made future proof. The new and improved canister – together with the proven X-SMART piston pump design – ensure your colorants won’t dry out and guarantee consistent colorant quality.

To give you a better insight please watch the animation of the piston pump.

Dramatic increase in speed

With the X-PROTINT®, waiting times during peak hours are history. The bigger pump, together with the bi-directional and faster turntable, make the X-PROTINT® twice as fast as the X-SMART and the TM280.

See it yourself in the dispense speed comparison movie of the X-PROTINT vs TM280.

Technical data

General

- Automatic sequential

- X-PROTINT® Solvent based, water based, universal

Canisters

- Up to 16 canisters canisters

- Material: Polymeric (POM)

- Size: 2.3/4.6 l

Pump

- Piston pump

- Size: 43 ml

- Flow rate: 0.5 l/min

- Min. dispense: 0.077 ml (1/384 fl. oz.)

- Nozzle diameter: 4 mm

- Polymeric needle valve

- Seals material: Teflon & Viton

- Copied calibration - No recalibration required

Nozzles

- Air tight - Integrated nozzle closures

- Nozzle cleaning system: passive brush

Can table

- Manual shelf

- Dimensions: 38 x 35 cm (WxD)

- Loading height: 25 cm

- Max. can height: 41 cm (50 cm no shelf)

- Optical can sensor

Dimension & weight

- HWD 123 x 82 x 87 cm

- Filling height: 115 cm

- Packaging HWD 142 x 98 x 98 cm

- Weight net: 126 kg

Power supply & safety

- 110V +/- 10%, 50Hz/60Hz

230V +/- 10%, 50Hz/60Hz - No certifications

Options

- Solvent version

Accessories

Can positioning light

Can positioning light

The can positioning light shows the operator were the middle of the can shelf is, in order to place a can straigth underneath the dispensing point of the machine.

Can positioning light

Stand alone punch 46mm or 48mm

Stand alone punch 46mm or 48mm

An external punching system in order to punch a hole into the lid of the can to be able to dispense through the punched hole. The stand alone punch is available in 2 different punch knife sizes of 46 or 48 mm.

Stand alone punch 46mm or 48mm

News

Meet our X-PROTINT 24c

Enter the X-PROTINT 24c — the ultimate automatic dispenser that offers high performance, reliability, and simplicity. Say goodbye to operational complexity and maintenance headaches with its user-friendly interface and ready-to-use design that ensure easy installation...

X-PROTINT: more canisters for more demanding environments

Do you have a need for more than 16 canisters to create the perfect tinting solution? You can now also opt for an X-PROTINT with 24 canisters for more demanding environments.

Technical Insights

Technical Insights (December 2021)

To answer the supply chain challenges caused by COVID-19 constraints and component shortages, our engineers and developers have been looking for – and finding – alternative ways to improve our tinting machines. Read about our...

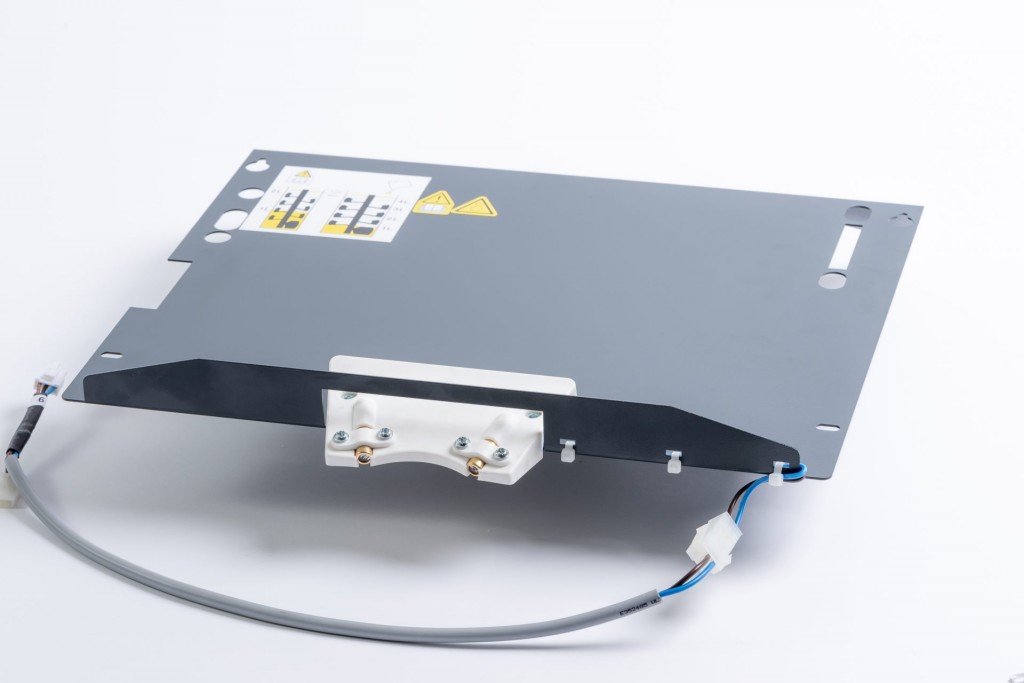

New board V2 X-PROTINT

New printed circuit board for X-PROTINT dispenser

Complementary

PrismaRT mobile tinting application

PrismaRT is a cloud-based innovative mobile tinting application compatible with all our X-series dispensers. It brings the best of wireless technology without the accompanying cost of investment in hardware.

GX300 automatic mixer

- Medium and high volume paint turnover

- Automatic, dedicated control

- Max. product weight: 40kg

- Variable speed (slow start), between 230 and 100 rpm, dynamic balance

SK550 1.1 heavy-duty paint shaker

- Medium and high volume paint turnover

- High/Low clamping detection

- Max. product weight: 40kg

- Speed: up to 680 shakes per minute - variable speed (slow start); contact us for optimal settings

SK300 and SK300 PRO

- Low and medium volume paint turnover

- Current controlled clamping

- Max. product weight: 35kg

- Speed: up to 680 shakes per minute

PrismaPro2 POS tinting software

Control all aspects of your POS tinting software with PrismaPro. It's compatible with all our automatic dispensers. Fueled by 15 years of customer insights Prisma Pro has grown to be an outstanding solution for demanding operators and engineers.